|

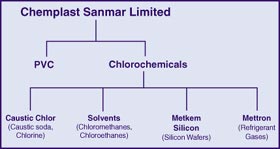

Set up in 1962, Chemplast Sanmar Ltd (CSL)

(formerly Chemicals & Plastics India Ltd) is the flagship of the

Chennai-based Sanmar Group. It acquired Mettur Chemicals, a maker of

caustic soda, in the late 80s. With this CSL integrated backwards as

Mettur also manufactured an equivalent quantity of chlorine. CSL then

set up various forward integration facilities for using the captive

chlorine production. It started manufacturing chloromethanes,

refrigeration gases (CFCs), hydrochloric acid, stable bleaching

powder, water treatment chemicals, trichloroethanes etc. Metkem

Silicon Ltd, manufacturing silicon wafers using chlorine, was then

merged with CSL.

CSL has plants located at Mettur Dam and

Vedaranyam, Krishnagiri & Panruti in Tamil Nadu.

During FY99, the company restructured its

business, vesting its shipping business with Sanmar Shipping Ltd (SSL).

CSL now focuses only on chemicals, with one of the divisions

manufacturing PVC and the other making chlorochemicals -- caustic

soda, chlorine, solvents, refrigerant gases and silicon wafers.

The PVC division of the company, commenced

operations in May 1967 at Mettur, near Salem in Tamil Nadu with

technology from B.F. Goodrich, USA. The division produces a varied

range of high quality PVC Resin products with a wide range of end use

applications. The division has a capacity: 60,000 MT per annum

It manufacturer of 3 grades of Suspension

Resins, 3 grades of Paste (Dispersion) Resins, 2 grades of Copolymer

Suspension Resins plus a speciality Battery Separator Resin. It is

also the only manufacturer of Battery Separator grade Resins (made

with technical know-how from ICI, UK) and Copolymer Suspension Resins

in India.

The PVC business of Chemplast Sanmar is

integrated backwards i.e., it gets its feedstock, industrial alcohol,

from its alcohol plants at Panruti, near Neyveli and from Krishnagiri,

near Dharmapuri and chlorine from its neighbouring chlor-alkali

facility. It has the necessary port-based infrastructure to import

feedstock like ethylene dichloride (EDC). It has a captive power

generation capacity of 10 MW in the PVC plant, meeting 100% of its

requirements. The chlor-alkali plant also has 30 MW additional power

generating capacity, with the option to augment this capacity through

wind mills

The plant presently has the capacity to

produce,Suspension and Copolymer Resin with a capacity of 40,000 TPA,

Paste Resin with a total capacity of 16,000 TPA, Battery Separator

Resin 4,000 TPA thereby totaling a capacity of 60,000 TPA.The Mettron

business commenced operations in October 1988 and manufactures

Chlorofluorocarbons (CFC) and Hydrochloro Fluorocarbons (HCFC)

The Mettron business commenced operations

in October 1988 and manufactures Chlorofluorocarbons (CFC) and

Hydrochloro Fluorocarbons (HCFC). The manufacturing facility is

located at Mettur, near Salem in Tamil Nadu .The plant capacity is

2,500 MT per annum of CFC and HCFC

The first Caustic Soda plant was set up in

1936 by The Mettur Chemical and Industrial Corporation Limited (MCIC).

MCIC was merged with Chemplast Sanmar Limited in 1988. The business is

now has a fully integrated plant with a 100% captive power generation

facility. The manufacturing facility is located at Mettur, near Salem

in Tamil Nadu. The business contributes significantly to the

development of the caustic soda industry in the country.

The plant has a capacity to produce 48,000

mt of caustic soda per annum and 42,000 mt of chlorine per annum.

The PVC business has also recently

commissioned the Oxy Chlorination plant to increase production of

captive feedstock - EDC and projects to augment Ethylene and Paste

resin capacity are underway.

The PVC business will concentrate more on

speciality resins, strengthening its market leadership. Its current

goals include commercialising a speciality terpolymer solution vinyl

resin, CP 510, having applications in printing inks for metal

decoration and gravure printing on polyester. A 170,000 TPA

shore-based PVC plant is being planned at Cuddalore, Tamil Nadu

Under the terms of the Montreal Protocol,

the production and use of CFC-11 and CFC-12 will have to be phased out

by the year 2010. The gradual process of phasing out these products is

to be completed in stages: 50% by 2005, 85% by 2007 and 100% by 2010.

Chemplast`s production programme will be in line with the above

phase-out. The Mettron business will continue to produce HCFC-22,

which has a phase-out deadline of 2040.

For More information see

www,sanmargroup.com/chemicma.htm Contact's

| ||||||||||||||||||||